Ferrybridge C Power Station in West Yorkshire was commissioned by the Central Electricity Generating Board and was built between 1962 to 1968. The ‘C’ Station was the third power station to be built at Ferrybridge. The ‘A’ Station building remains and is now used by RWE as their national heavy engineering facility. The ‘B’ Station was demolished after its closure in 1992.

Ferrybridge C had a capacity of 2 GW from four x 500 MW generating sets supplied by CA Parsons. The CEGB chose Ferrybridge to trail the new 500 MW units, the world’s first single-line turbogenerator sets of this size.

In addition to the main generating units, Ferrybridge C Power Station was built with four gas turbines with a combined capacity of 68 MW. Two of the four gas turbines were retired in the late 1990s, reducing their capacity to 34 MW.

Coal was supplied initially via barges on the Aire and Calder Navigation Canal, utilising a barge tippler capable of unloading 210 ton barges in nine minutes. The tippler was retired in the late 1990s and an automated system was built to receive deliveries via rail.

Cooling water was drawn from the River Aire and after circulating through the power station, was cooled using the station’s 8 cooling towers. The towers were 115m high. The plant had two 198m chimneys. Ash was transported as a slurry via underground pipeline to the Gale Common Ash Disposal Site.

Flu Gas Desulphurisation was fitted to units 3 and 4 in 2009. This allowed those units to meet the requirements of the Large Combustion Plant Directive (LCPD), while units 1 and 2 were closed on 28th March 2014. In 2013 SSE announced the station would opt out of the EU Industrial Emissions Directive. Ferrybridge C generated its last electricity on 23rd March 2016. The reasons stated were “irreparable damage” caused by a major fire in 2014, and that the station was now a loss-making operation, predicted to lose £100 million over the following five years.

Buildings and Plant Detail

The water treatment plant ensured purity of the water used for steam

Ferrybridge C Image Gallery

Visit the plant detail pages above to view more images from each area of the power plant

2014 Fire at Ferrybridge C

On 31st July 2014 a serious fire broke out in the Flue Gas Desulphurisation (FGD) Plant for unit 4. Unit 3 was also affected by the fire. Neither unit was operational at the time due to maintenance. Unit 3 returned to service on 29th October 2014, and unit 4 on 15th December 2014. The fire had completely destroyed the FGD of unit 4, meaning that unit had to burn very low sulphur coal in order to comply with emissions regulations. The supply of very low sulphur coal ran out in March 2015, at which point unit 4 was retired. The one remaining unit was closed a year later, the reason stated by SSE was “irreparable damage” caused by the fire resulting in a loss-making operation.

Cooling Tower Collapse

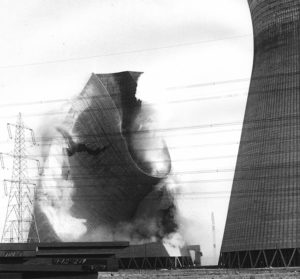

The cooling towers at Ferrybridge C power station were arranged in two parallel staggered rows, 350ft apart. Each cooling tower was 350ft high, with diameters at the base of 350ft, at the throat 165ft and at the top 180ft. All were constructed of reinforced concrete shells 5 inches thick. Construction of the cooling towers was completed in 1964.

On the morning of Monday 1st November 1965 a gale was blowing at Ferrybridge, with a wind speed of 44 m/s at the top edge of the cooling towers (a wind speed that occurs around once every 5 years at Ferrybridge). Vortices formed between cooling towers of the first row, loading the towers of the second row. The vortex frequency was approximately the same as the natural frequency of the towers (0.6 Hz).

The vortex loading caused three of the four towers in the second row to collapse. An eyewitness said that some towers where moving like belly dancers. The second tower from the southern edge of the leeward row (tower 1B) collapsed first, at about 10.30am. The one immediately north-west of it (tower 1A) collapsed about 10 minutes later and the one north-west of that tower (tower 2A) at 11.20am. All three were in the leeward row and were fully completed.

The collapsed towers were replaced and the remaining towers were strengthened with an extra thickness of reinforced concrete.

Turbine Hall

Turbine Hall Boiler House

Boiler House Control Room

Control Room Water Treatment Plant

Water Treatment Plant Admin, Workshops & Bathhouse

Admin, Workshops & Bathhouse Coal Plant & Barge Tippler

Coal Plant & Barge Tippler

24 thoughts on “Ferrybridge C Power Station, West Yorkshire”

Yes For 34 Years I Worked at FerrybridgeCPower Station.

Started work at Ferry C in 1964 as A P A, was on Unit 1 control panel when it was first put on the bars and had the honour of taking Unit 1 of the bars for the final time.So got my 50 years in.

Had the best 15 years at C Station and was a pleasure when I was on unit 1 with you Brian and of course Malcolm ?

Did my time as an electrical fitter at C station from 1976 to 1980, I always wanted to work there and I loved the place and the people. In 1980 there were very few spaces for lads coming out of their time, so many of us ended up at Drax which frankly wasn’t the same kind of ‘pit culture’ environment I’d enjoyed at Ferribridge C.

It will be a sad day when the chimneys come down.

Worked at Ferry C from 1983 until closure. It was the best times of my working life and made many good “mates”. It will be a very sad day for many when the old girl is demolished.

My Dad worked at C station in the sixties, I was across the way on ops at B Stn. However, I was brought in to support the C site closure safety programme and having worked for RWE at the A station, I guess I can say I’ve worked at all three sites!

Hi Martin,

My name is Jack Whitehouse and I am part of a group from the Manchester School of Architecture and we are currently undertaking research on the Ferrybridge Power Station site. Looking into all the Power Stations that have stood on the site A/B/C and now the multi fuel stations.

We are looking for people who will be willing to be interviewed and can share their working life experiences and an insight into the Ferrybridge Power Stations. Interviews will be conducted by zoom or email and can be short and informal as you like.

If you are happy to undertake an interview/chat or would like further details, please contact me either replying to this message or emailing jack.whitehouse2@stu.mmu.ac.uk

This will be much appreciated and really beneficial for our studies.

Have a great Christmas,

Kind Regards,

Jack

Over 27 years I have worked at all the Power Stations in the area and beyond. My last 10 years being at “Ferry C ” in the Mill Bay Team. I enjoyed it so much I did a further 2 years and retired at 67…… That says something about the Station.

Senior moment, should be 40 years in the industry, 27 was up to Thorpe Marsh closing inn 1994. Drafted in to Ferry C in 1998 from Drax to help rebuild Unit 4. Then stayed on till retirement.

In 1964 and 1965 I worked on the design of the Ratcliffe and Didcot cooling towers for the consulting engineers C S Allott and Son. They were also supervising the construction of the towers at Ferrybridge but hadn’t been involved in the design. I had the drawings for Ferrybridge and raised my concerns when I noted that there was significantly less reinforcement in them than in Ratcliffe and Didcot. I was asked to make a detailed check on the Ferrybridge towers. I concluded that the safe design wind speed was 45 mph, and that the reinforcement would fail in one area of the shells at 68 mph. Fortunately, after receiving my report, the site manager stopped all work inside and near the shells when winds exceeded 45 mph. On the day of the collapse, the wind was gusting to 72 mph.

I designed the strengthening of the 5 towers which remained standing. The three towers which collapsed were rebuilt to a similar design wind speed to those at Ratcliffe and Didcot. I went out to site to supervise the rehabilitation works.

Unfortunately, I have lost contact with the team who worked on the rehabilitation of the towers.

I was invited by the decommissioning contractor to watch the demolition of the 5 towers in 2019.

The power station has served the country well !!!

Your last sentence is moving. These truly were cathedrals of power. The people who built them, operated and fed them working underground are/were heroes providing a backbone for the nation. My uncle was one of them. I don’t forget.

Yes I Worked Here

Ferry C , The best thermal generation plant to work on in the world, Mick Gee and his great staff created a safety culture second to none, all contractors on site were part of the team promoted to work as one, every problem or issue shared. It worked perfectly with all working together to keep the old girl running, keeping us all safe and providing everyone on site with a sense of achievement, comradery and a very productive work ethic. With the dark Yorkshire crack (humour) thrown in. Loved every shift of it even New Years eve 2012 sorting 4A ID fan out! A true role model for industrial plant operation and management.

Hi Paul,

My name is Jack Whitehouse and I am part of a group from the Manchester School of Architecture and we are currently undertaking research on the Ferrybridge Power Station site. Looking into all the Power Stations that have stood on the site A/B/C and now the multi fuel stations.

We are looking for people who will be willing to be interviewed and can share their working life experiences and an insight into the Ferrybridge Power Stations. Interviews will be conducted by zoom or email and can be short and informal as you like.

If you are happy to undertake an interview/chat or would like further details, please contact me either replying to this message or emailing jack.whitehouse2@stu.mmu.ac.uk

This will be much appreciated and really beneficial for our studies.

Have a great Christmas,

Kind Regards,

Jack

I worked here from 1986 to 1996 on Operations. I was an Operations foreman until they got rid of them. Was also a Unit operator. I previously worked at B station 1977 to 1986. Enjoyed my time at this site. I can remember working with Brian Hornsby, and Martin Viggars. Went on to work in the CHP division and on the Windfarms within the operations and health and safety departments. Now happily retired.

Hi Martin,

My name is Jack Whitehouse and I am part of a group from the Manchester School of Architecture and we are currently undertaking research on the Ferrybridge Power Station site. Looking into all the Power Stations that have stood on the site A/B/C and now the multi fuel stations.

We are looking for people who will be willing to be interviewed and can share their working life experiences and an insight into the Ferrybridge Power Stations. Interviews will be conducted by zoom or email and can be short and informal as you like.

If you are happy to undertake an interview/chat or would like further details, please contact me either replying to this message or emailing jack.whitehouse2@stu.mmu.ac.uk

This will be much appreciated and really beneficial for our studies.

Have a great Christmas,

Kind Regards,

Jack

My name is Jack Whitehouse and I am part of a group from the Manchester School of Architecture and we are currently undertaking research on the Ferrybridge Power Station site. Looking into all the Power Stations that have stood on the site A/B/C and now the multi fuel stations.

We are looking for people who will be willing to be interviewed and can share their working life experiences and an insight into the Ferrybridge Power Stations. Interviews will be conducted by zoom or email and can be short and informal as you like.

If you are happy to undertake an interview/chat or would like further details, please contact me either replying to this message or emailing jack.whitehouse2@stu.mmu.ac.uk

This will be much appreciated and really beneficial for our studies.

started work ay Ferrybridge `c` straight from school September 1974 ,first year at Harrogate training centre completing a 4 year craft apprentice ship city and guilds by 1978. first years on shift maintenance moving onto day work in 1980 on the coal plant team,2000 moved back upto the main station on the boiler team, completing outage works and boiler repairs. with the station looking to reduce staff levels, applied for retirement and left in October 2014, watched the horrific fire of the absorber tower from the main muster point, which ultimately closed the station, after leaving for a short period was asked to carry out safety monitoring duties on the deconstruction of the badly damaged absorber,finally walking through the gates in 2017, What a great place to work with some very good colleagues.

I worked for STC that supplied the start up/shut down sequence control system and associated alarm systems for Ferrybridge C Station.

I am trying to create a record of the system and cannot find any photographs or documentation which will be helpful

Can anyone help with this or be prepared to talk to me about it? or tell me where I can find such information

if so you have my email address and my telephone number id 01865 873343

Thank you

David Harverson

My dad ,Kazimierz “Henry” Dobrowolski worked at Ferrybridge A &B in the control room. I was born 1956 so I think my dad might have started in 57 or58

Ran the staff canteen at Ferry C from 1985 to 1990 after doing my first 5 years at Ferry A. Best job I ever had and the happiest of times, until privatisation kicked in. Worked with some lovely women, most sadly no longer with us, but remained friends for years. Dad worked there too. Working on the construction early 60’s then as a crane driver in the turbine house..i think. So sad it has now all gone

I work for National Grid so was regularly in and out of the power stations. Was the (de)Commissioning Officer for the closure and got to learn some real history about the place, I’ve even kept the dials off the old Synch Trolley!

I remember looking at replacing some of the circuit protection there in 2007 and we went up on the substation roof to look at where to put an aerial. What a view.

Called back early this year after watching the demolition and it’s so depressing it’s gone.

Gone are the days when the government would build 2000MW power stations… now all we get are less than 100MW “bio mass” plants or solar farms on land.

What was the cooling water demand for Ferrybridge C? How much water did she abstract from the River Aire?

The three CW make-up pumps had a maximum capacity of 17,500 gal/min. Unsure of actual demand.