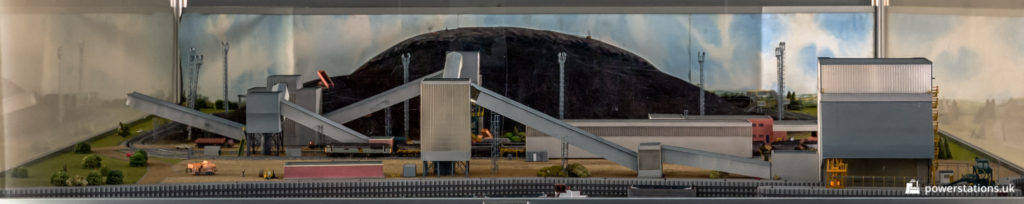

The coal store at Ferrybridge ‘C’ Power Station had a capacity of 1 million tons of coal, and received the majority of its coal from the nearby Kellingley Colliery.

Coal was supplied by a combination of rail transport with 1,000-ton merry-go-round trains at the rate of 17 a day supplying 4 million tons of coal per year, and coal transported by barges along the Aire & Calder canal, via Knottingley and then through Ferrybridge lock.

Barge transport ended in the late 1990s. Built by Rhymney Engineering, the new automatic unloading equipment for the trains used ultrasonic detection. This system could deal with up to 99 wagons in a train to control the door-opening gear, emptying 5 wagons at a time into the bunkers.

The Ferrybridge Barge Tippler

A 2,000 MW station requires a lot of coal, which traditionally took a long time to unload. It was announced in October 1964 that at Ferrybridge a coal discharging installation was built to raise and tip 210 ton barges in nine minutes. Coal would be delivered in trains of three compartment boats, propelled by a powerful tug.

The barge tippler was a large unloading hoist which raised the boats 12m above water level, discharging the coal into an elevated receiving hopper which fed the conveyor system leading to the power station. By this means an unloading rate of 1,000 tons per hour was achieved.

The system was designed by Strachan and Henshaw Ltd., of Bristol. On arrival at Ferrybridge, the barge trains were led into a channel approaching the unloader. At this stage they were taken in by a marshalling system and the tug moved away downstream to collect awaiting empty trains. After being re-assembled into a train, empty boats were back to Kellingley Colliery.

The manufacturers claimed that this system of water-borne transportation and handling could make a considerable contribution to industrial efficiency. The use of a tippler enabled barge carriage to compete favourably with, and be independent of, all other forms of transport wherever there is reasonable water access from the supplier to the customer.

After much research had been undertaken into the Ferrybridge installation, the Railway Board attempted to make out a case for delivery of coal to the power station by rail. The CEGB was convinced of the striking superiority of the barge system, which was able to go ahead as planned.

Use of the barge tippler was discontinued in the late 1990s when a new rail delivery system was installed, and all deliveries were made by either rail or truck from then on.

Barge Tippler Pictures

Document and Schematics

24 thoughts on “Ferrybridge C Power Station”

► Read comments or add your own on the main page