Opening in 1959 Uskmouth B is one of the UK’s oldest remaining coal-fired power station. The station was also described as the UK’s least efficient plant before it was closed pending a conversion to biomass in 2015.

The power station is a fantastic example of 1950s architecture. The main buildings are brick, the use of which was phased out shortly after construction in favour of metal-clad steel structures. The station’s single stack is one of the finest remaining fluted chimneys in the UK.

The power station is a fantastic example of 1950s architecture. The main buildings are brick, the use of which was phased out shortly after construction in favour of metal-clad steel structures. The station’s single stack is one of the finest remaining fluted chimneys in the UK.

The power station originally had three English Electric generating sets, producing a total of 363 MW of electricity. The station was commissioned by the Central Electricity Generating Board (CEGB), and was handed over to National Power when the electricity industry was privatised in 1990.

The station closed in 1995, and was subsequently purchased by AES in 1998. The station underwent a £120 million refurbishment which was completed by 2001. The refurbishment increased the generating power to 393 MW and new environmental equipment was installed to bring it up to date with legislative requirements.

One of the three 131 MW generators was mothballed in 2013, and a year later the entire power station was closed. The station was subsequently sold with plans to convert the boilers to fire Biomass. Uskmouth B re-opened briefly, still burning coal until an explosion caused extensive damage to the station’s switch house in April 2017. The station did not re-open following the explosion and is now being decommissioned.

Buildings and Plant Detail

Plant Services & Worker Facilities

Plant Services & Worker Facilities

Various services around the site and facilities for workers.

Uskmouth Image Gallery

Visit the plant detail pages above to view more images from each area of the power plant

Turbine Hall

Turbine Hall Boiler House and Coal Delivery

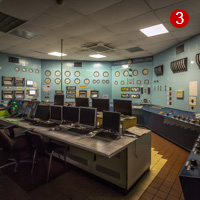

Boiler House and Coal Delivery Control Rooms

Control Rooms

10 thoughts on “Uskmouth B Power Station, Newport”

I worked there Briefly employed as an Unit Operator Sept 2004 to June 2005 enjoyed my short time there but gained useful hands on of Coal Fired plants being a Former Pembroke Oil fired man yes happy place to work

I worked here for a long time. Started as an APA on the dust plant and mills, PA on water treatment and riverside pumpsman, Assistant Unit Op on all 3 boilers and turbines, Unit Op on all three and finished as one of the site SAP’s and shift team leader.

If I haven’t broken it or fixed it, they haven’t got it!!

It was a long time, under several owners, a good, solid team of people made this station a long term success.

Worked there as an Assistant Chemist 1978 to 1981. Great plant to work at. Remember the boiler chemical cleans. Happy days.

Hi Geoffrey, my Grandfather is Mike Davies. I’ve heard him talk about you many times! I have many happy memories of visiting the Power Station as a child!

Was a student apprentice working in both A and B Stations and 132Kv switchouse in the mid 60’s. Sorry to see the dusty (asbestos!) A Station be consigned to scrap, it’s 6 x 60MW units were more reliable than the ‘newer’ B station’s 120MW ones. Good to see that the B station is being rejuvenated to more modern standards. What is up with Unit 15?

Ken,

Great to hear your comments on your time spent at Uskmouth. Units 13 and 14 will be converted to fire waste derived pellet fuels with unit 15 remaining un-converted.

The project includes a 20 yr relifing and general modernisation to get the most from the units in the future. We will keep this station going with the professionalism, dedication and team spirit of old!

I’d love to hear more about the A station as it was gone before my time on site – what boiler/combustion system was used on the 6 units?

Uskmouth A. If my memory serves me well! 12 boilers each of nominal 40Mw (E) capacity 900deg F 900psi into a range system feeding 6 Parsons turbines each of 60MW. so theoretically spare boiler capacity. Flue dust extraction was provided partially by electrostatic precipitators running at 50Kv provided by mechanical (yes mechanical!) rectifiers, running syncronised to 50 Hz, there was a distinct smell of ozone in the air anywhere near them, They were a awsome picture to behold when they became unstable, the arms drew a circular arc of crackling sparks about 5 ft diameter!

In the early days when sets 1 to 4 were running and set 5 was being commissioned, the exciter to set 5 was to be switched off as part of the tests. Unfortunately the excitor to set 4 was switched off by accident, hence with no electrical load set 4 oversped, The mechanical overspeed bolts which should have tripped the set did not work ( investigations later showed deposits has seized the bolts). No idea what speed the turbine reached but it eventually exploded, live steam everywhere parts of the LP rotor blades were found on the opposite bank of the Usk. Parts of the LP rotor also went straight through a thick brick wall into the the boiler house and severed a 14inch (?) pipe – luckily it was an atmospheric pipe, it would have been a different story if the adjacent steam range pipe had been severed! Poor set operator amid destruction and live steam, managed somehow to close the stop valve to the turbine, a heavy and slow job – but somehow he did it. An exciting time but when fully commissioned the A station provided a long and reliable service more reliable than the B station.

What lovely memories I have of Uskmouth ‘B’ and ‘A’ Power Stations. I worked at both Plants having moved from RTB Steelworks beforehand.

Not long married, I learned so much from the older, more experienced guys. The Foremen, I remember so well. Old fashioned types, Bob McDonald,Tom Hicks, Fred James, who had a twin brother, Bob ( training Engineer), Jack Turley, Jack Haydock??, from London, and so many others. My nicest memories are when, if I was lucky to be in the Control Room of a night, was three of us singing. Frank Davey, Jim Baker and I would sing as only Welsh guys can, and as we had three different voices, 3 part harmony! Me, Tenor, Jim, Baritone and Frank Base. That Control Room could have been The Royal Albert Hall!! You cannot buy memories can you?? God Bless

Nice Photo,s.

I worked on the 3 Tin Cans for over 40 Years , the smell of Steam and Turbine Oil ahh!!. The best Unit was 14 , just with the Oil on to lift the Shaft in the Bearings , it would turn by itself. Something rare to see , 75 Ton of Shaft in perfect Alignment.

Wacka Evans.

I was a student apprentice there from ’63 to’67 before moving on to Nottingham, then Fiddlers Ferry and Pembroke-and then on to NZ and Perth, Western Australia. Now back in The UK near Swansea. I well remember my first day there being left to wander around, starting at the top at drum level from the lift and walking along the girder walk trying to overcome the shock of looking through the grating down to the operating floor level.

Still look over to the right when on the M4 going east to see that stack.